Hermle Machine Company

Across manufacturing sectors, smart manufacturing, flexible automation, and Industry 4.0 (I4.0) have shifted the dynamic for small job shops. Bridging the gap between custom craftsmanship and mass production, the boutique firearm industry is pioneering a transformation of its own. The next generation of small firearm shops promises high-quality, customizable firearms at competitive prices and quicker turnaround times. Whereas the first industrial revolution was about mass production, I4.0 is about mass customization.

“Smart manufacturing and Industry 4.0 technologies have fueled a significant investment in automation across sectors like aerospace, automotive, and precision tools,” says Gunther Schnitzer, president and CEO of HERMLE USA. “We now see small manufacturers in these industries competing in the production of high-performance parts. The firearm market is mirroring this trend, creating a tremendous opportunity for boutique shops to capture market share through advanced manufacturing and customization capabilities.”

Arnot Heller, president of Detroit Gun Works, a mechanical engineer, business owner, and machinist explains his reason for adopting the next-generation machining solution from HERMLE: “The transition to the fully digital shop floor is real no matter the size of your shop. For the last four years, we’ve had the machining capabilities to execute our version of the fully digital shop, shortening our development cycle and building a customizable machined product for our discerning customer base.”

The Detroit Gun Works team has always been driven by a commitment to action. For four generations, they’ve been cutting metal, building tools, and continually investing in the latest technologies to meet their customers’ needs. Detroit Gun Works remains dedicated to craftsmanship, innovation, and the unwavering values that have defined the company from the beginning.

Cutting-edge technology

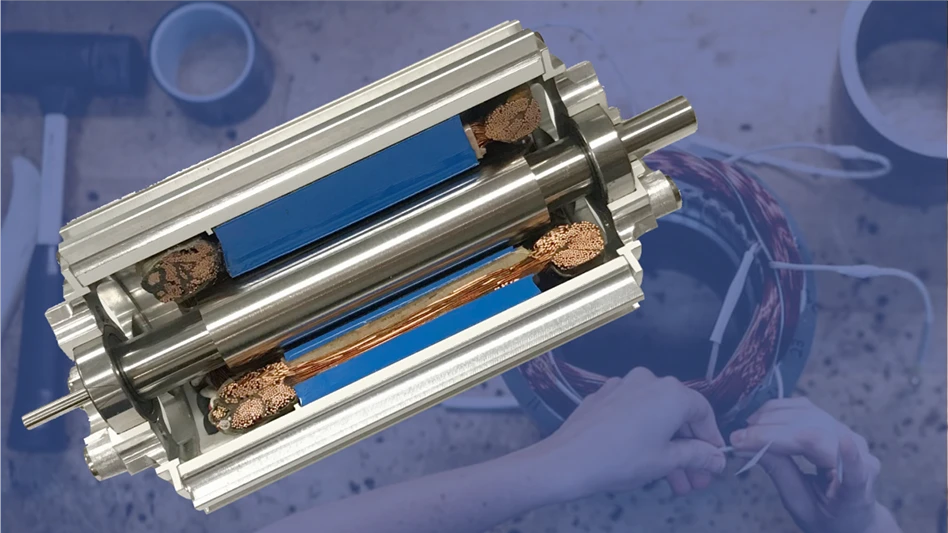

Custom firearm makers using advanced tools have reduced retail prices by up to 20%, making custom firearms more accessible to mid-tier buyers. The HERMLE C 250, and 5-axis machining centers like it, have given these smaller manufacturers a competitive edge. In a market where quality often comes with high prices and long wait times, the game is changing. Five-axis machines streamline the process by handling complex parts in a single setup, eliminating the need for multiple transfers and setups. This efficiency results in shorter production cycles, faster turnaround times, and a reduced reliance on highly skilled labor. The future of firearm manufacturing is being shaped by agile players who combine cutting-edge technology with traditional craftsmanship.

“HERMLE provided more than just a capable machine; they provided a process to achieve the highest level of automated efficiency” ~Jimi Leslie, owner, JL Billet

“HERMLE provided more than just a capable machine; they provided a process to achieve the highest level of automated efficiency,” says Jimi Leslie, owner of JL Billet. “We keep the spindles going and maximize that volume knowing the quality is reliably replicable. The details of our parts have always set us apart, but the ability to automatically run batches of prototypes, unsupervised, overnight, without sacrificing quality, made this next step a no-brainer for us. From aluminum to stainless steel, we maintain flexibility and precision without chasing tolerances or filling the scrap bin.”

Achieving tolerances down to the micron, premium 5-axis milling machines deliver the standard demanded by high-performance industries and the precise quality a craftsman can love. By delivering high-value, tailored firearms, small manufacturers are catering to larger markets with products combining affordability, speed, and craftsmanship.

A survey from The Outdoor Wire found an increasing number of firearms buyers are seeking custom firearms, as many are interested in making personal modifications, especially in the hunting and competitive shooting markets. Customization was specifically noted as a growing priority over price alone, and now that price gap is closing. This trend marks a new era of opportunity where custom firearm makers can leverage quality and affordability while targeting the premium middle ground between custom and mass-produced firearms.

As advanced technologies such as 5-axis milling continue to lower costs and improve efficiency, custom firearm makers are uniquely positioned to meet the growing demand for high-quality, personalized products – delivering a seamless blend of small shop tradition and innovative production.

Detroit Gun Works

https://detroitgunworks.com

HERMLE USA

https://www.hermleusa.net

JL Billet

https://jlbillet.com

Explore the March 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- HII installs first additively manufactured valve manifold assembly on aircraft carrier

- V2X to sustain electronic warfare systems for U.S. Air Force

- Maximize your First Article Inspection efficiency and accuracy

- Pratt & Whitney awarded $1.5 billion F119 engine sustainment contract for Air Force F-22 fleet

- Safran DSI secures contract with Bell Textron to deliver flight testing solutions, antennas

- C3 Suite of managed solutions to fast-track CMMC Level 2 certification

- Armada Systems, Inc delivers mission critical edge software, hardware solution to the U.S. Navy

- BAE Systems secures $251 million contract to support U.S. Navy’s AEGIS Combat System