IperionX Limited

IperionX Limited has executed a Test Services Agreement and Statement of Work with the U.S. Army Combat Capabilities Development Command Ground Vehicle Systems Center (DEVCOM GVSC). This agreement will focus on the metal characterization and ballistic testing properties of IperionX’s high-strength titanium plate components.

DEVCOM GVSC may relay the results to select U.S. DoD contractors who are original equipment manufacturers (OEMs) of U.S. Army ground vehicles for consideration in future ground vehicle designs. Known U.S. Army ground vehicle contractor OEMs include:

- General Dynamics Land Systems, an arm of General Dynamics Corporation

- BAE Systems, Inc., the U.S. subsidiary of BAE Systems PLC

- American Rheinmetall Defense, Inc., the U.S. counterpart of Rheinmetall AG

- Oshkosh Corporation

- AM General, a privately held firm based in South Bend, Indiana

The titanium plate for U.S Army ballistic testing will be manufactured using powder metallurgy production methods with IperionX’s advanced titanium angular powder. To deliver higher performance and durability, IperionX will also employ its patented Hydrogen Sintering and Phase Transformation (HSPT) technologies, a cutting-edge technique to enhance the microstructure of titanium to deliver strength and fatigue properties that are comparable to wrought titanium alloys.

Titanium is prized for its high strength-to-weight ratio, resistance to high temperatures and corrosion. Titanium is a critical material for many U.S. defense systems, including military fighter aircraft and engines, naval platforms, and military ground vehicles. Titanium’s superior strength-to-weight and corrosion resistance offers scope for future U.S. Army ground vehicles to be lighter, more mobile and with enhanced range and durability in the field.

The United States has very limited domestic primary titanium metal (titanium sponge) capacity and currently imports over 95% of the titanium sponge required for the U.S. defense sector. IperionX plans to re-shore a fully integrated titanium supply chain to the U.S., reduce the acute reliance on titanium imports from foreign nations, and strengthen the domestic titanium supply chain for critical defense systems.

The U.S. Department of Defense (DoD) is actively pursuing alternatives to the current import-dependent supply chain for titanium metal and alloys. The DoD aims to establish domestic operations from mining, processing, and refining of ore, as well as the recycling of scrap titanium. The optimal domestic titanium supply chain will provide a wide range of products - including titanium powder, ingots, bars, and plate – at higher energy efficiency, lower costs, and lower environmental impacts.

“We look at the combination of advanced manufacturing and titanium to help us improve both corrosion mitigation and light-weighting in Army ground vehicles," says Brandon Pender, Associate Director GVME, GVSC Head of Materials and Manufacturing. "Any relationship that we can pursue to make titanium more affordable as IperionX can potentially do, is valuable to us. The potential to produce titanium plate, with all of its capabilities, that is cost-competitive with aluminium and steel only helps us improve the operational performance and readiness of Army ground systems.”

“We’re honored to collaborate with DEVCOM GVSC to evaluate our titanium products for U.S. Army ground vehicles," says Anastasios (Taso) Arima, IperionX CEO. "Titanium for the U.S. defense sector is currently sourced over long distances from foreign nations. IperionX plans to re-shore a lower cost and more sustainable fully integrated U.S. titanium supply chain that is critical to America’s economic future and national security.”

Latest from Defense and Munitions

- Elbit Systems awarded $335 million total in contracts to supply European defense systems

- Trillium Engineering achieves breakthrough accuracy in GPS-denied environments

- Kaman’s high-precision non-contact displacement sensors

- IMTS 2024 Booth Tour: JTEKT

- Skunk Works demonstrates airborne battle management of AI-controlled aircraft

- Bell Textron tabs Integris Composites as armor supplier for Future Long Range Assault Aircraft

- Lantek's v44 software

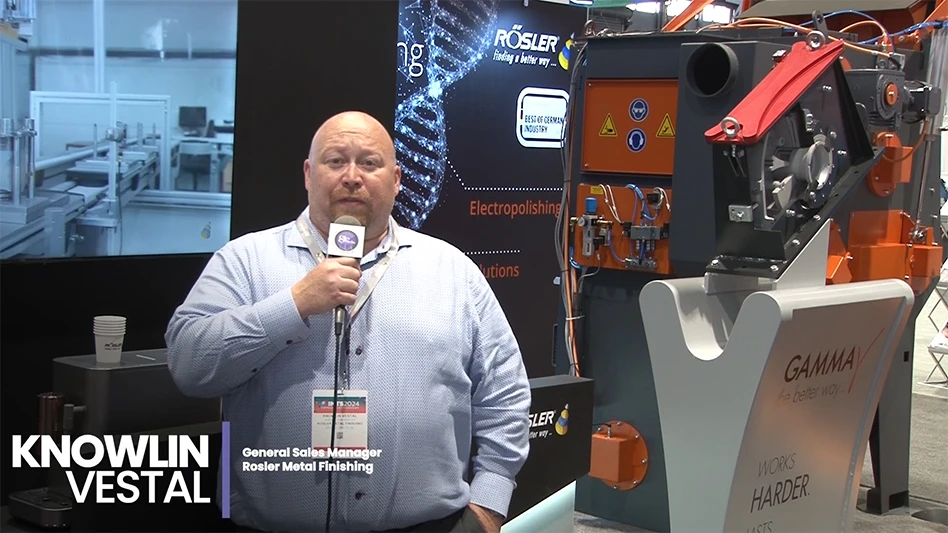

- IMTS 2024 Booth Tour: Rollomatic