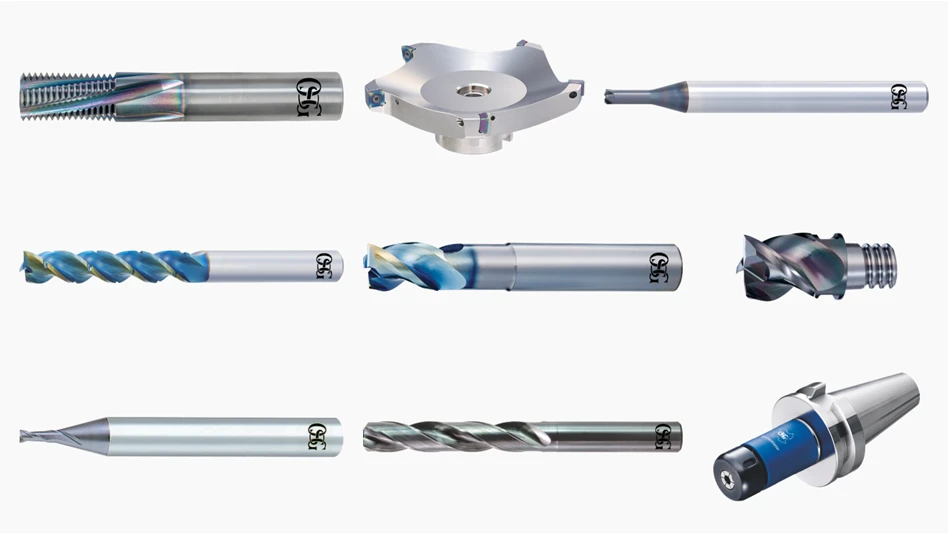

OSG USA, Inc.

OSG USA, Inc. is pleased to announce the announce the following new additions to the OSG product line up:

Expansion of the EXOCARB WXL-CR-EDS end mill series

The EXOCARB WXL-CR-EDS is a series of premium high performance carbide end mills for pre-hardened & hardened steels that now include inch size offerings.

The EXOCARB WXL-CR-EDS end mill offers the following features & benefits:

- Incredible wear resistance - Ultra-fine micro-grain carbide offers the hardest most wear resistant carbide possible for incredible wear resistance

- High accuracy/high precision geometry - High accuracy all but eliminates need for benching and rework for mold makers

- Ultimate strength and rigidity/high strength core diameter - Tools utilize thicker core diameters for the ultimate in strength and rigidity

- +1100 Celsius oxidation temp. & +3100Hv in hardness - WXL coating provides higher coating oxidation temp & hardness dramatically improve wear resistance

Expansion of the Synchromaster tap holder

The SynchroMaster is a next generation synchronized tap holder designed to turbocharge tapping performance and now includes an inch straight offering.

The SynchroMaster Tap Holder offers the following features & benefits:

- 1-Part construction

- ER16 & ER32 sealed collects

- Metal flexure mechanism

HY-PRO CARB ALD carbide drills

The HY-PRO CARB ALD is a performance carbide drill for non-ferrous materials.

The HY-PRO CARB ALD offers the following features & benefits:

- Double margin for improved stability & hole straightness

- Polished flutes allow for smooth chip evacuation and less BUE at the cutting edge

- X-Thinning and R-Gash for sharp & smooth cutting at the center

- Straight cutting edge for lower thrust force at high speeds

- Large chip pockets enhance chip evacuation while maintaining stability

- h6 reinforced shank compatible with standard tool holders

Expansion of the A Brand A-Tap series

The A Brand A-NPTF is an advanced performance pipe tap suitable for a variety of materials and now features the A-NPTF.

The A Brand A-NPFT offers the following features & benefits:

- Interrupted thread for reduced cutting torque

- Variable lead flute accelerates chip evacuation

- Enhanced cutting geometry to eliminate galling

- V Coating for exceptional wear resistance

Expansion of the A Brand thread mill series

The A Brand AT-1 is an advanced performance one-pass thread mill suited for a variety of materials and now features the NPS-style AT-1.

The A Brand AT-1 offers the following features & benefits:

- EgiAs coating for exceptional wear resistance

- Right-hand cut & left-hand helix geometry increases tool stability

- Ultra-fine grain carbide for high wear resistance and toughness

- Unequal spacing/variable lead flute for reduced vibration

The A Brand AE-HFE-H end mill series

A Brand AE-HFE-H is a series of advanced performance end mills for high-hardness steels.

The A Brand AE-HFE-H end mill offers the following features & benefits:

- Composite radius shape optimized for flat surface machining

- Double-stage gash design balances cutting edge strength and chip evacuation

- Variable index suppresses chattering

The PHOENIX PFDC indexable face mill cutter & inserts for non-ferrous materials

The PHOENIX PFDC & Inserts for Non-Ferrous Materials an exchangeable face mill cutter perfect for small machining centers.

& Inserts for Non-Ferrous Materials

The PHOENIX PFDC offers the following features & benefits:

- Thin steel body is lightweight and maintains high tool rigidity

- Internal coolant allows for improved chip evacuation

- Achieves high speed rotary machining

- Breaker shape with sharp cutting edge is ideal for non-ferrous material machining

- Easy tool management - No special arbor required

- Use with BT30 - Total weight under 3kg

Expansion of the A Brand AE-N end mill series

The A Brand AE-NIK-TL-N is a series of advanced performance DLC coated end mills for non-ferrous materials and now includes the AE-NIK-TL-N.

The A Brand AE-NIK-TL-N offers the following features & benefits:

- Center cutting ideal for plunging

- Large core & new flute form enhances rigidity and allows for excellent chip evacuation

- Unique cutting edge that achieves high durability and good surface finish

- DLC coating provides superior surface accuracy

- Nicked edge breaks chips into manageable shapes

Expansion of the A Brand AE-N end mill series

The A Brand AE-TS-N is a series of advanced performance DLC coated end mills for non-ferrous materials and now includes the AE-TS-N.

The A Brand AE-TS-N offers the following features & benefits:

- Center cutting ideal for plunging

- Large core & new flute form enhances rigidity and allows for excellent chip evacuation

- Unique cutting edge that achieves high durability and good surface finish

- DLC coating provides superior surface accuracy

The PHOENIX PXM PXAL exchangeable head end mill

The PHOENIX PXAL DLC coated exchangeable head end mills, designed for non-ferrous materials.

The PHOENIX PXM PXAL offers the following features & benefits:

PHOENIX PXM PXAL Exchangeable Head

End Mill

- Flat cutting edge achieves higher precision machined surface quality

- Center cutting edge allows this tool to be used for plunging

- XP4625 allows for welding resistance and long tool life in non-ferrous materials

- DLC-IGUSS coating improves durability and effectiveness for on-ferrous materials

- Extensive lineup including square type, radius type, and reduced shank type are available to accommodate a wide range of applications

OSG is a leading manufacturer of taps, end mills, drills and indexable cutting tools. OSG’s high technology cutting tools features exclusive metallurgy, cutting geometries and proprietary surface treatments to help increase productivity, reliability, and tool life. OSG also serves the fastener industry by offering a complete line of thread-rolling, flat, cylindrical, planetary, and trim dies.