Ceratizit

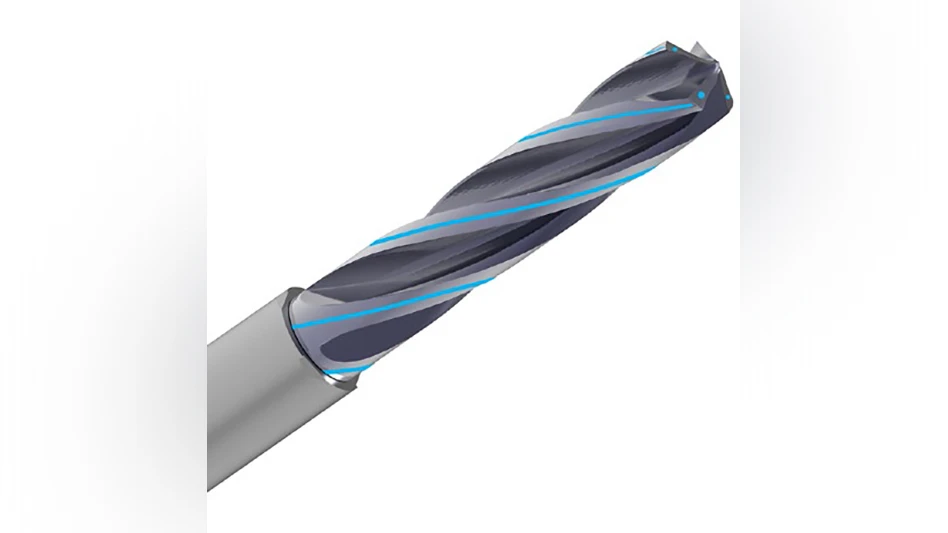

The innovative pyramid geometry of the WTX-HFDS ensures extremely aggressive and precise drilling performance. It achieves positioning accuracy of 0.03mm and has excellent centering properties. The cutting force is distributed to four cutting edges for longer tool life. The core stability of the drill is retained due to optimum cooling via four internal spiral coolant holes which makes the drilling process accurate and effective.

When the WTX-HFDS is coated with CERATIZIT’s Dragonskin coating technology, it offers a higher level of protection against wear. Designed with an impenetrable layer, it manages the most adverse conditions and requirements. A combination of state-of-the-art high-performance substrates and new coating structure enables high cutting speeds and increased process security.

With its precision in design and excellence in manufacturing, it achieves new levels of drilling quality, hole tolerance, and positioning accuracy. Four through-coolant holes deliver optimum cooling of each cutting edge, allowing for considerably higher tool life. This also results in a noticeable reduction in tool costs. Additionally, there’s low burr formation when entering and exiting the hole which means little to no subsequent deburring is needed.

The CERATIZIT WTX-HFDS solid carbide drill provides immediate cost savings by reducing machining time and improving cycle times.